Graphite Disk Keeps Rotating to Produce Muons

- The Challenge under International Collaboration

between Japan and Switzerland -

The points of achievement

∗ Institute of Materials Structure Science, High Energy Accelerator Research Organization (IMSS-KEK) has been conducting experiments utilizing muons that are produced by irradiating proton beams on a graphite muon target at the Japan Proton Accelerator Research Complex (J-PARC).

∗ To cope with the world's most intense pulsed proton beam, a rotating target was developed under collaboration with Paul Scherrer Institute (PSI) in Switzerland, which had developed the target in advance. However, the target was suffering from the fact that the bearings supporting the rotating body would fail within a year.

∗ The group in IMSS-KEK achieved long-term operation of the high-intensity beam from 2014 to 2019 by adopting a new kind of bearing that can achieve a longer life.

∗ The same bearings were also used at PSI, and consequently one year of stable continuous operation was achieved in December 2021.

Abstract

Institute of Materials Structure Science, High Energy Accelerator Research Organization (IMSS-KEK) has been conducting research in materials life science and fundamental physics by using muon beams of the world's highest quality and intensity. The muon beams are produced by irradiating proton beams on a graphite muon target at Japan Proton Accelerator Research Complex (J-PARC). Under the technical collaboration with Paul Scherrer Institute (PSI) of Switzerland, which had developed the target in advance, the development of a rotating target that can withstand high-intensity proton beam has been promoted at J-PARC as well. However, the bearings that support the rotating body fail within a year in Target E at the world most intense continuous proton beam facility HIPA of PSI, requiring the experiments to be stopped and the target to be replaced. Therefore, the group in IMSS-KEK developed the rotating target taking advantage of a new kind of bearing that could achieve a longer life. By adopting these bearings, the long-term operation from 2014 to 2019 was realized. Based on these results, the same bearings were adopted at PSI, and in December 2021, the stable continuous operation period reached one year, the best after a long period of several bearing failures at PSI. J-PARC and PSI, the world's two major muon facilities, are good rivals in science, and at the same time, they are striving to improve their technologies through mutual collaboration. This technology can be applied to various rotating target in the world's high-intensity accelerators.

Background

Currently, 17 elementary particles are known, but the most familiar ones are photons and electrons, (protons and neutrons, which create matter, are also familiar, but they are composite particles made from quarks and are not elementary particles).

A Muon is an elementary particle classified as a lepton in the same family of an electron and was discovered in cosmic rays in 1936. Although the muon is about 200 times more massive than the electron, they have similar properties, such as having the same negative electric charge as the electron.

So far, we use photons and electrons in various purposes, and muons are also beginning to be utilized by taking advantage of their properties. For instance, muons contained in cosmic rays are used to see through the inside of pyramids and nuclear reactors because of their high transparency. At J-PARC, a world-class proton accelerator artificially produces large quantities of muons for research in material and life sciences and fundamental physics. Recently, it became a popular topic that components enclosed in "Kouan Ogata's medicine box", an ancient medicine box out of glass, was nondestructively identified by the muons produced at J-PARC.

There are technical challenges in keeping producing large quantities of muons for a long period in the high-intense proton accelerators. Muons are produced by the immediate decay of pions created by irradiation of the proton beam into a 20 mm thick graphite muon target. Normally, the beam path around the muon target is kept in an airless vacuum to prevent the proton beam, pions, and muon beams (Note 1) from colliding with air and being lost. Simultaneously, heat is generated on the muon target when exposed to the proton beam, and since there is no air to release the generated heat, it is important to find a way to cool the target.

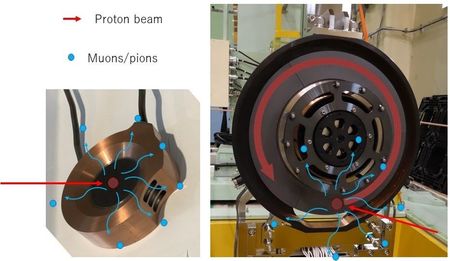

In the Materials and Life Science Experimental Facility (MLF), IMSS-KEK is in charge of the development of the graphite muon target that produces muons. When the beam operation started in 2008, a fixed target is applied for the muon target (Figure 1 left). In the fixed target, since a graphite disk with a diameter of 70 mm is bonded to a copper frame, the heat on the center of the muon target is removed by thermal conduction in the graphite. J-PARC aims to increase the intensity of the proton beam to obtain more muons, and when the beam reaches its current designed intensity of 1 MW, 3.3 kW of heat and irradiation damage will occur on the graphite. This irradiation damage results in the loss of the graphite's ability to conduct heat and in localized shrinkage of the graphite. Due to this damage, the muon target is anticipated to fail within one year in the fixed target. Once the muon target fails, the MLF must be shut down for more than three weeks to replace it. Therefore, it was necessary to extend the lifetime of the muon target to continue the MLF experiments in a stable manner.

The problem of graphite being damaged by proton beam irradiation can be solved by avoiding irradiating the same spot with proton beams. However, the proton beam must pass through the exact center of the beamline, and it is not easy to move the proton beam itself. For this reason, a method called a rotating target has been introduced. In the rotating target, the proton beam position is not moved, but the graphite itself is rotated to disperse the damage on the graphite over a wide area (Fig. 1, right). Similarly, the heat is widely dispersed and is cooled by thermal radiation (emission of light).

PSI has been conducting research using muons as well as J-PARC and has been using a rotating graphite target as a meson target (Note 2) since 1985, before the construction of the J-PARC MLF. The members developing the muon target at J-PARC have visited the meson facility at PSI since the construction of the J-PARC MLF and have referred shared information from many researchers and engineers for development of the proton beamline and the muon target. PSI has been operating two types of rotating targets, Target M and Target E. At that time, the Target E, which is a high-intensity target, had a problem that the bearing supporting the rotation body broke down within a year, and the experiments had to be stopped and the target had to be replaced.

Research and results

Bearings supporting rotating body are composed of an outer ring, an inner ring and multiple balls between the rings. Lubricants are used to reduce friction between the balls and the rings. Normally, organic functional material, grease, which has properties between those of a solid and a liquid, is used as a lubricant. However, the grease cannot be used for bearings in rotating targets because it releases a lot of gas into the vacuum at high temperature and is affected by high radiation environment due to proton beam irradiation. Therefore, it is necessary to use solid lubricant made of inorganic materials that are less affected by irradiation and release less gas. The life of a rotating target bearing is greatly affected by the type and shape of the solid lubricant, and PSI has used bearings coated with molybdenum disulfide or silver as solid lubricants for inner and outer rings, balls, and a ball-separator (Figure 2 left). However, if the coatings peel off, the bearings lose their lubricating performance. Therefore, J-PARC adopted a bearing (JTEKT Corporation: WS bearing) in which lumps of tungsten disulfide (bottom right of Fig. 2), an inorganic material, is inserted between the balls (top right of Fig. 2). In this case, the amount of lubricant is far greater than in the case of coating, and thus a longer life can be expected.

The bearings selected in this way were assembled into a prototype of the rotating target for validation, where they underwent a series of rotational tests with heating to high temperatures in a vacuum. According to the results of these rotational tests, it was decided to use bearings specially designed for the J-PARC MLF with an improved solid lubricant shape. Finally, the rotating target #1 was installed in the proton beamline in 2014 and had stably operated for 5 years. The rotating target #2, which was replaced in 2019, has achieved stable operation with a beam intensity of 0.83 MW until now in 2022, while the beam intensity has been gradually increased. It also successfully operated at the beam power of 1 MW for 32 hours. Because of the stable operational record of this bearing at J-PARC, we offered PSI to adopt the bearing with the same lubricant and geometry, and after two years of rotational tests, the Target E implementing the bearings was installed in the beamline. As a result, in December 2021, one year of stable operation was achieved, which is the best after a long period of several bearing failures at Target E of PSI. This achievement has given us the prospect of providing muon beams for experiments without losing beamtime.

J-PARC and PSI, the world's two major muon facilities, are good rivals in science, and at the same time they are striving to improve new technologies through mutual collaboration. This technology can be applied to rotating targets used in accelerators around the world that are aiming for higher intensities.

It can realize continuous production for large quantities of muons in the future project, which is expected to accelerate research in material life science, particle physics, and other fields.

Original publications

[1] S. Makimura et al., "Muon production target at J-PARC MLF", J. Particle Accelerator Society of Japan, Vol. 18, NO. 4, 2021, p202-209, written in Japanese.

[2] S. Makimura, et al., "Perspective of Muon Production Target at J- PARC MLF MUSE", Proceedings of the 14th International Conference on Muon Spin Rotation, Relaxation and Resonance (μSR2017), JPS Conf. Proc. 21, 011058 (2018)

DOI: 10.7566/JPSCP.21.011058

[3] Things run smoother without lubricants

https://www.psi.ch/en/science/scientific-highlights/things-run-smoother-without-lubricants

[4] D Kiselev, et al., "The Meson Production Targets in the high energy beamline of HIPA at PSI", SciPost Phys. Proc. 5, 003 (2021)

DOI: 10.21468/SciPostPhysProc.5.003

Significance and future prospect

J-PARC and PSI, the world's two major muon facilities, are good rivals in science, and at the same time they are striving to improve new technologies through mutual collaboration. This technology can be applied to rotating targets used in accelerators around the world that are aiming for higher intensities.

It can realize continuous production for large quantities of muons in the future project, which is expected to accelerate research in material life science, particle physics, and other fields.

(Note 1) In the following, "pions and muons" are abbreviated as "muons" if there is no need to distinguish between them.

(Note 2) According to category of pions, which are the source of muons, PSI call them meson targets.

Figures

Figure 1: Fixed target (left) and rotating target (right). The rotating target disperses the damage and heat generated by the proton beam. The bearings supporting the rotating body determine the life of the target.

Figure 2: Conventional bearings using solid lubricants are coated with molybdenum disulfide or silver on the balls, an outer ring, an inner ring, and a ball separator (left); J-PARC uses a bearing with lumps of tungsten disulfide (bottom right) inserted between the balls (top right).

"We knew that chromium possesses strong corrosive resistance, but the superelasticity, flexibility, and significant wear resistance of the cobalt-chromium-based material surprised us," added Xu.